|

|

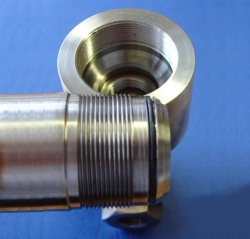

The screw-fit end cap contains the viton (DuPont) O-ring and the lock ring required for higher pressure

sealing. The fine gauge thread used on the cap ensures a progressive torque build to the sealing O-ring.

Also within the test cell itself can be seen the metal-metal seal used in this burst disc application.

A 'square' shoulder representative of the port geometry seen in many burst disc and O-ring combinations

rather than m-m seal, could also be made and tested at temperature.

|

|

Fig2: Detailed view of test cell port geometry

|

|

|

We can vary the bursting pressures by suitable choice of foil thickness and correction factors

being applied. In the pictures shown is a burst disc in its post test state.

|

|

Fig3: Detailed views post test discs

|

|

|

Pressures at these elevated levels are recorded by us in 5psi increments. At normal lower

operating pressure levels the equipment is capable of reading-out in single psi figures. It

is regularly calibrated to ensure consistency

Test cell temperatures within the oil bath are recorded both pre and post test - the

average being the 'declared' temperature.

|

|

Fig4: Calibrated digital pressure read-out

|